Bulk material is separated into two or more products on the basis of either bigger than or smaller than a certain size hence the alternate term ‘size control’ for screening.

Minerals are separated on a high frequency screen for sizing and grading purposes.

Single or multiple deck screens with different opening sizes are used to separate aggregate material into different size categories for further treatment or stockpiling as saleable product.

The induced high frequency vibrations ‘shakes loose’ dust and fine particles clinging to large particles to achieve optimal efficiency.

Easily adaptable angles is employed to decrease or increase flow rates and ensuring ideal flow rate for maximum efficiency.

Easily interchangeable wire mesh panels with various aperture configurations provide unmatched versatility and adaptability.

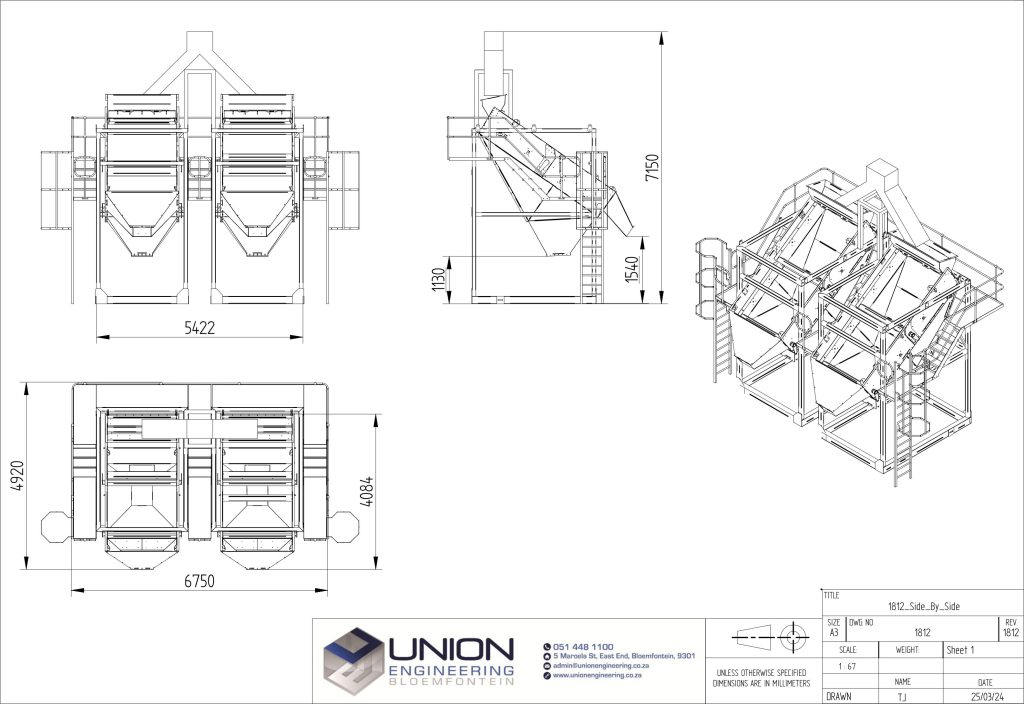

Mineral Processing Division produces various models of high frequency screens.

Easily interchangeable wire mesh panels with various aperture configurations provide unmatched versatility and adaptability.

Using a ‘modular’ approach, the basic screen can be complemented with a scalping deck to separate oversized minerals.

These illustrations and videos showcase our design philosophy based on versatility, and minimum handling of material and cost saving.

By combining the in house metal fabrication capacity with the output of the screening division. The company supports the capacity to retrofit the screens or even design ‘tailor made’ screens to add to existing facilities.

NKWE Crush and Quarry

Plateau Mining

Woema Crushers

Bastion Burhmansdrift

Bastion Marble Hall Lime Chem

Bastion Britten

SAKG Witkop

SAKG Kannakies

SAKG Sallies

KDR

KDR

Hamze Trading

Blaze Coastal Mining

Afrimat Vredendal

Afrimat Marble Hall

Afrimat Robertson

P & B Lime

Tip Trans

K1 Quarries

Raumix

JV Projects Highveld

JV Projects Steelpoort

Pistorius Highveld

Mooiplaats

Idwala Port Shepstone

Idwala Danielskuil

Brick Mecca

Northern Namibia Development

Tisalux

Buckle Crushers

Gorrakop

KLP Trade

Wonderstone

Kasimira Trading

Marx Vervoer

Ladybrand Crushers