Bulk material is separated into two or more products on the basis of either bigger than or smaller than a certain size hence the alternate term ‘size control’ for screening.

Sized particles being separated on a high frequency screen for sizing and grading purposes.

Allows for precise separation of fine materials, typically down to 1 mm level for all grain cleaning needs

Pre screening or scalping can be employed to remove the oversized material, after which the main screening deck will remove undersized material, leaving a perfectly sized product.

Easily adaptable angles is employed to decrease or increase flow rates and ensuring ideal flow rate for maximum efficiency.

Easily interchangeable wire mesh panels with various aperture configurations provide unmatched versatility and adaptability.

Illustrating a design philosophy based on versatility

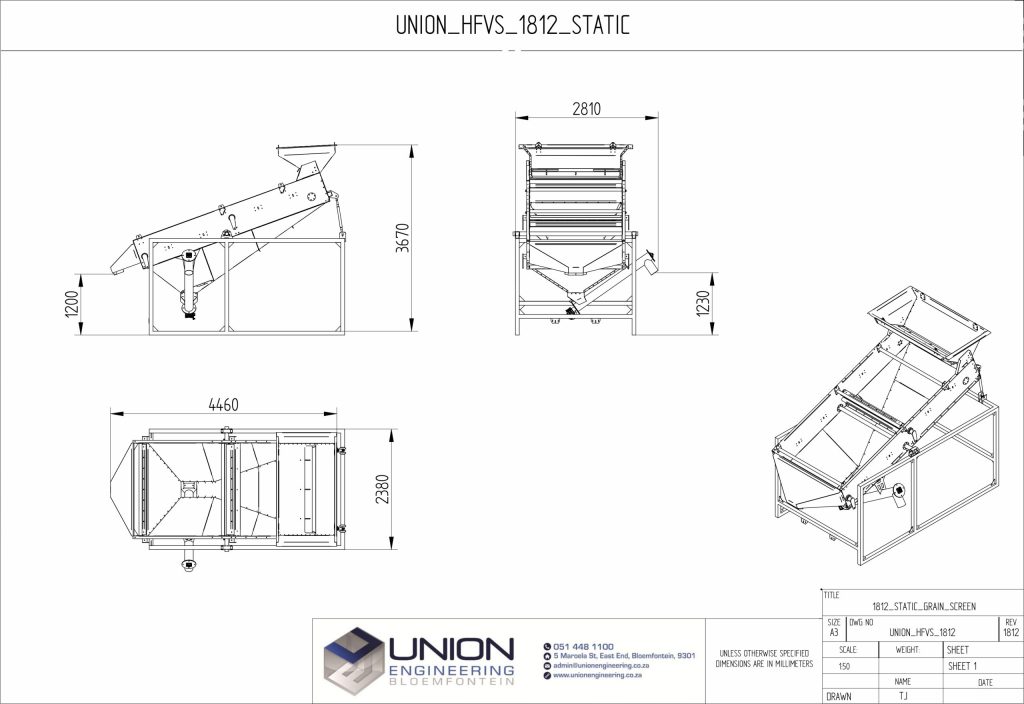

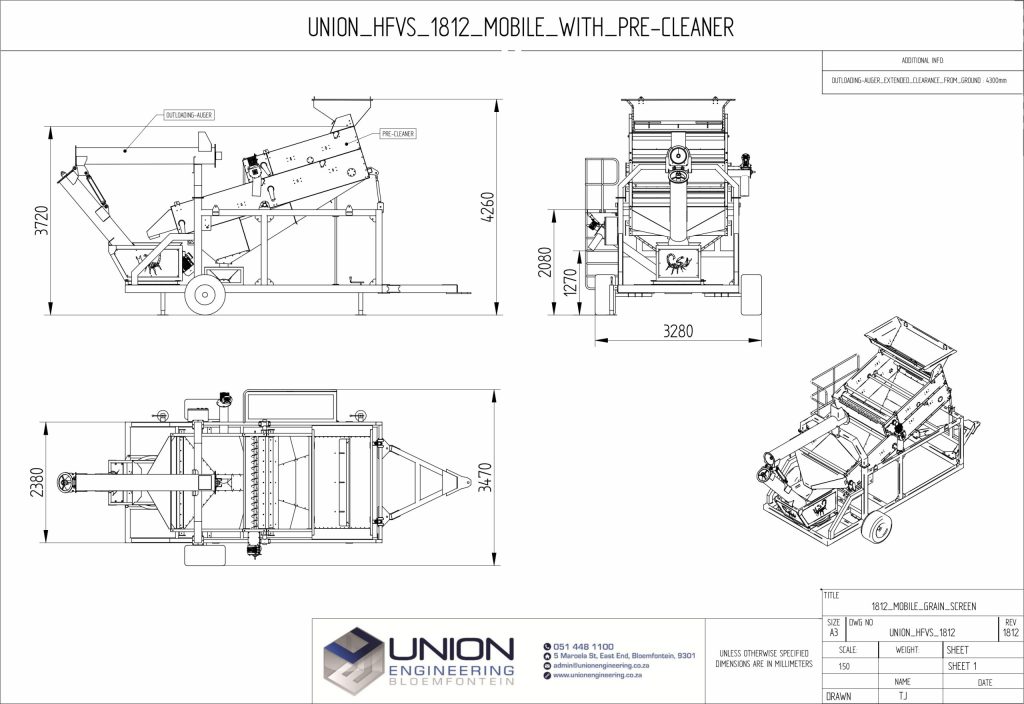

Union Engineering now boasts a Grain Cleaning Division that builds two standard models of static screens and two standard models of mobile screens, ‘Sifting’ is discharged by means of an Auger designed to handle between 8 and 12 % of feed tons.

Easily interchangeable wire mesh panels with various aperture configurations provide unmatched versatility and adaptability, allowing the user to switch from maize to soybean to sunflower to wheat/oats to canola within an hour.

Using a ‘modular’ approach, the basic screen can be complimented with a pre cleaner to separate, for example, green soy pods from soybean seeds with an auger to discharge the green pods before the soybeans are discharged onto the actual screening decks for Sifting and a ‘load out’ auger can discharge the clean grain directly into waiting for trucks illustrating a design philosophy based on versatility, and minimum handling and storing of grain above all simplicity.

By combining the in house metal fabrication capacity with the output of the screening division. Union supports the capacity to retrofit the screens into existing silo complexes or even design ‘tailor made’ screens to add to existing storage facilities.

Icon Foods

1212 Mobile

Marius Erwee

Riaan Taljaard

Mel Olivier

Silostrat Kleinhoek

Maritz Wolfaardt

Kallie Snyman

Sarel van der Walt

Albertus Brink

AJ Calits

Jacques van Zyl

Kosie Nel

Grain screen site information

Jaco Prinsloo

RSP Farming Solutions

Dion van Dyk Silkstar

Jacues Botha

NWK Bodenstein

NWK Grain Silo

NWK Coligny

NWK Grain Silo

NWK Boschpoort

NWK Grain Silo

NWK Boons

NWK Grain Silo

NWK Derby

NWK Grain Silo

NWK Grootpan

NWK Grain Silo

NWK Silo 5

NWK Grain Silo

NWK Sannieshof

NWK Grain Silo

NWK Delareyville

NWK Grain Silo

NWK Oppaslaagte

NWK Grain Silo

NWK Herbenia

NWK Grain Silo

NWK Syferbult

NWK Grain Silo

NWK Migdol

NWK Grain Silo

NWK Ottosdal

NWK Grain Silo

Dawie Pretorius

JP van Jaarsveld

Hendrik Wessels

Rudi Swanepoel

Prima Pasta

Deon Berg

Milne Bredenkamp

Mike Prinsloo

Silostrat Sarbyn

Christoff

Flippie

Moereson Pluimvee

Frik van der Merwe